Perfluoropolyether oil

Perfluoropolyether oil

Base oil:

CL100、CL101、CL102、

CL103、

CL104、CL105

Vacuum pump oil:

CL1506

CL1514

CL1525

Product Introduction

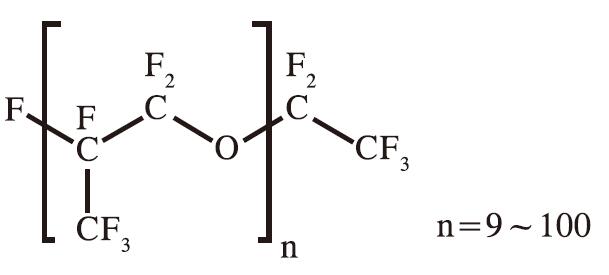

Perfluoropolyether oil is a colorless and transparent oily liquid at room temperature, resistant to high temperatures, chemical corrosion, oxidation, and radiation. It is mainly used as lubricating oil and vacuum pump oil. Due to its extremely high stability and safety, especially its high reliability under particularly harsh conditions, no working medium can compare to perfluoropolyether oil in such harsh environments.

Application

Nuclear IndustryWhen used as a bearing lubricant for high-speed centrifuges, PFPE is the only lubricating oil that can resist the chemical shock and low vapor pressure of uranium hexafluoride above 130 ℃;

Nuclear IndustryWhen used as a bearing lubricant for high-speed centrifuges, PFPE is the only lubricating oil that can resist the chemical shock and low vapor pressure of uranium hexafluoride above 130 ℃;- Chemical IndustryIn working environments with chemically corrosive gases, it can be used as a lubricant for various vacuum pumps, compressors, and valves:

- Medical, FoodSafe and non-toxic, can lubricate and seal, protect mechanical equipment, and extend its service life;

- Electrical IndustryLubrication of arc resistant switches and sliding wire contact components;

- Mechanical EngineeringBearings that can be used for high-speed operation, especially in extremely high temperatures and harsh environments, can extend the life of bearings by 5 to 50 times;

- Automotive IndustrySuitable for starter motors, electric rearview mirrors, door locks, manual (electric) glass lifters, manual brake lines, main reducers, butterfly brake cylinder pistons, clutch release bearings, brake master cylinders, etc., it can reduce component friction, reduce noise, and enhance user comfort;

- Electronic IndustryMechanical vacuum pump oil suitable for plasma etching of integrated circuits;

- Magnetic media IndustryCan be used as a lubricant for hard drives, disks, and other magnetic recording media on computers, DVD players, automatic recording devices, and other instruments;

Aerospace, MilitaryLubrication and sealing of gear pumps, valves, regulators, pressure gauges, metal joints, and threaded fasteners for liquid fuel and oxidizer systems in liquid fuel rocket engines; It is also used for lubrication and sealing of pipelines, valves, fillers in spacecraft oxygen supply systems, bearings in axial flow fans for transporting oxygen for respiration, and components of astronaut oxygen supply devices.

Aerospace, MilitaryLubrication and sealing of gear pumps, valves, regulators, pressure gauges, metal joints, and threaded fasteners for liquid fuel and oxidizer systems in liquid fuel rocket engines; It is also used for lubrication and sealing of pipelines, valves, fillers in spacecraft oxygen supply systems, bearings in axial flow fans for transporting oxygen for respiration, and components of astronaut oxygen supply devices.

Technical Parameter

| Performance Comparison | Conventional lubricants | Perfluoropolyether Oil |

|---|---|---|

| Oxygen | Slow oxidation, production of acid or sludge, severe oxidation, fire or explosion | No reaction, no combustion |

| High temperature | Accelerated oxidation, carbon deposition or coking accelerates volatilization and leakage | No carbon buildup, not easily volatile, and not lost |

| Water or humid environment | Emulsification, wetted by water | Insoluble |

| Chemical substances | Corroded by acids, alkalis, organic solvents, etc | Chemical stability |

| Contact parts | Corrosion sealing material lubricant leakage, damaging equipment | Wide material compatibility, no corrosion |

| Vacuum pump oil performance | CL1506 | CL1514 | CL1525 |

|---|---|---|---|

| Viscosity, cSt, ASTM D445 | |||

| 20°C (68°F) | 60 | 140 | 250 |

| 50°C (122°F) | 15.5 | 32 | 52 |

| 100°C (212°F) | 4.1 | 7.2 | 10.6 |

| Pour point ASTM D97 | |||

| ° C | -60 | -54 | -48 |

| ° F | -76 | -65 | -54 |

| Density, g/mL | |||

| 20°C (68°F) | 1.88 | 1.89 | 1.90 |

| 50°C (122°F) | 1.82 | 1.83 | 1.84 |

| 100°C (212°F) | 1.73 | 1.74 | 1.75 |

| 200°C (392°F) | 1.54 | 1.55 | 1.56 |

| Evaporation loss ASTM D2595, 22 hour mass loss (wt%) 121 ℃ (250 ℉) | |||

| 121°C (250°F) | 6.5 | 1.3 | 0.6 |

| Base oil performance | CL100 | CL101 | CL102 | CL103 | CL104 | CL105 |

|---|---|---|---|---|---|---|

| Applicable temperature range ℃ | <-70~66 | <-70~104 | <-63~132 | <-60~154 | <-51~179 | <-36~204 |

| ℉ | <-94~150 | <-94~220 | <-81~270 | <-76~310 | <-60~355 | <-33~400 |

| Viscosity, cSt, ASTM D445 | ||||||

| 20℃(68℉) | 7 | 16 | 36 | 80 | 180 | 550 |

| 40℃ (104℉) | 4 | 8 | 15 | 30 | 60 | 160 |

| 100℃ (212℉) | — | 2 | 3 | 5 | 9 | 18 |

| ASTM D2270 | — | — | 29 | 92 | 124 | 134 |

| Pour point ASTM D97 | ||||||

| ℃ | <-70 | <-70 | -63 | -60 | -51 | -36 |

| ℉ | <-94 | <-94 | -81 | -76 | -60 | -33 |

| 密度, g/mL | ||||||

| 0℃ (32℉) | 1.87 | 1.89 | 1.91 | 1.92 | 1.93 | 1.94 |

| 100℃(212℉) | 1.67 | 1.70 | 1.72 | 1.74 | 1.75 | 1.76 |

| Evaporation loss, ASTM D972, 22 hour mass loss (wt%) | ||||||

| 66℃ (150℉) | 11 | 2 | 2 | 1 | 1 | 1 |

| 121℃ (250℉) | 87 | 35 | 20 | 7 | 3 | 2 |

| 204℃(400℉) | — | — | — | — | — | 10 |

| Applicable temperature range ℃ | <-70~66 | <-70~104 | <-63~132 | <-60~154 | <-51~179 | <-36~204 |